About

Who we are

We are a pioneering software and hardware company that has been revolutionizing industries with cutting-edge AI technology since 2019. Headquartered in Bulgaria with a global team of top engineers, the company delivers innovative, accessible AI solutions that make a meaningful impact across industries. Its flagship product, the AI Feeder, is a compact, embedded AI camera that offers robust object recognition, 3D tracking, and real-time insights, supported by scalable hardware. Waves Vision also provides a comprehensive software platform that simplifies AI integration into workflows, particularly in manufacturing, where its AI Quality Control solutions ensure high product quality through reactive and proactive monitoring. Committed to innovation and accessibility, Waves Vision empowers industries with powerful yet user-friendly AI solutions.

- Quality Control : Advanced AI solutions for defect detection and prevention, ensuring high product quality in manufacturing.

- Manufacturing Monitoring : Real-time insights and proactive monitoring to optimize production processes and maintain operational efficiency.

- Premium Support : Tailored assistance and dedicated support to ensure seamless integration and minimize downtime.

AI Feeder

Quality Control

Empowering Innovation, Enhancing Efficiency.

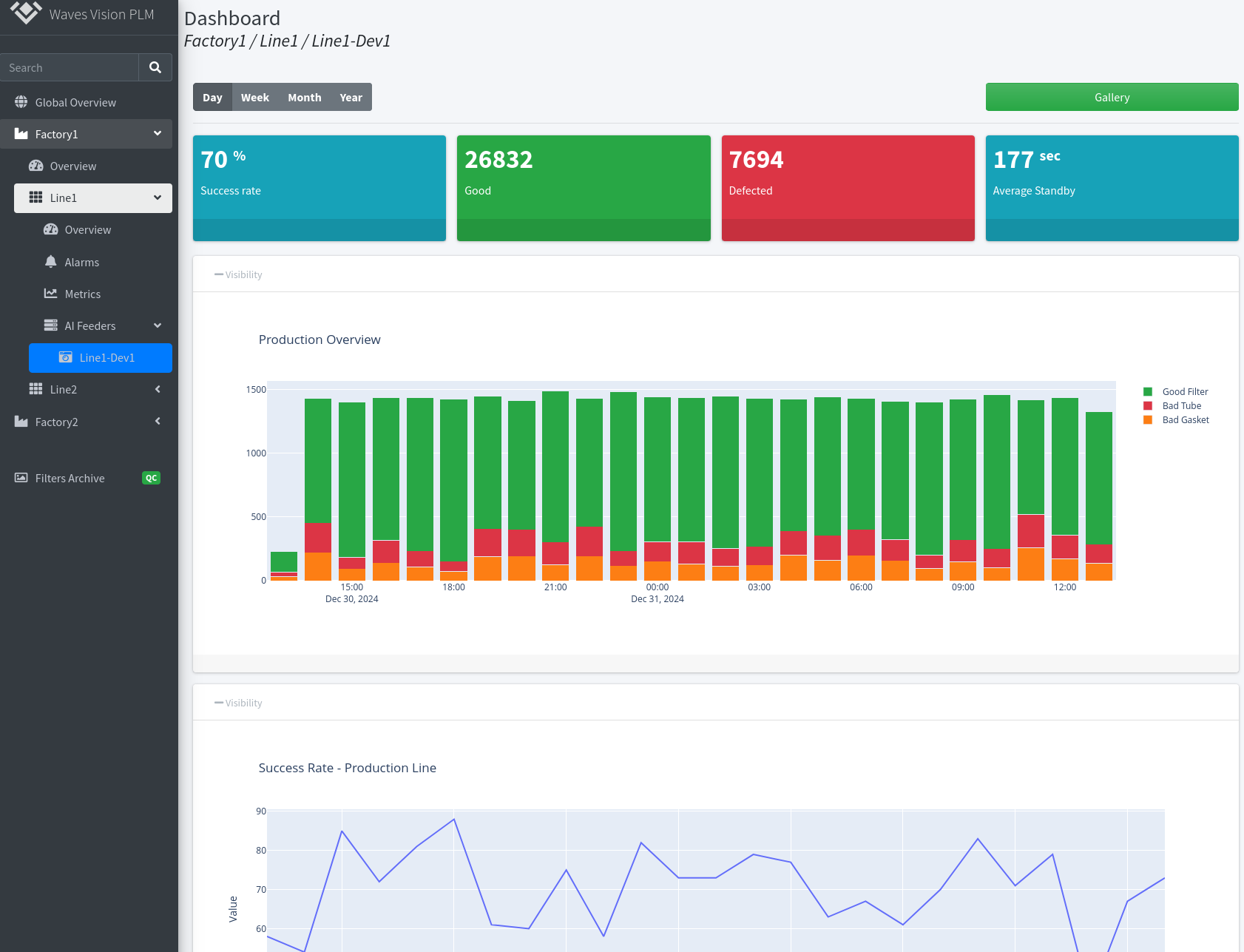

Monitor your production lines with our cutting-edge AI Quality Control, ensure unparalleled efficiency and accuracy. With reactive monitoring, it automatically detects known defects and integrates seamlessly into your workflows, ensuring only high-quality products reach your customers. Proactively, it detects anomalies and alerts your team, enabling quick resolutions and preventing future issues.

- AI Quality Monitoring : Automatically detects defects and integrates seamlessly into your workflows, ensuring high-quality products and preventing issues before they escalate.

- Proactive Anomaly Detection : Identifies potential problems early, enabling swift action and continuous improvement in your production processes.

- AI Feeder Device : A compact, powerful solution with advanced sensors and processing capabilities, designed to deliver real-time insights and enhance efficiency across various applications.

AI Feeder: Standalone Solution for Quality Control with Unmatched Precision!

Manufacturing

Monitoring

Cutting-Edge AI Monitoring.

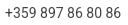

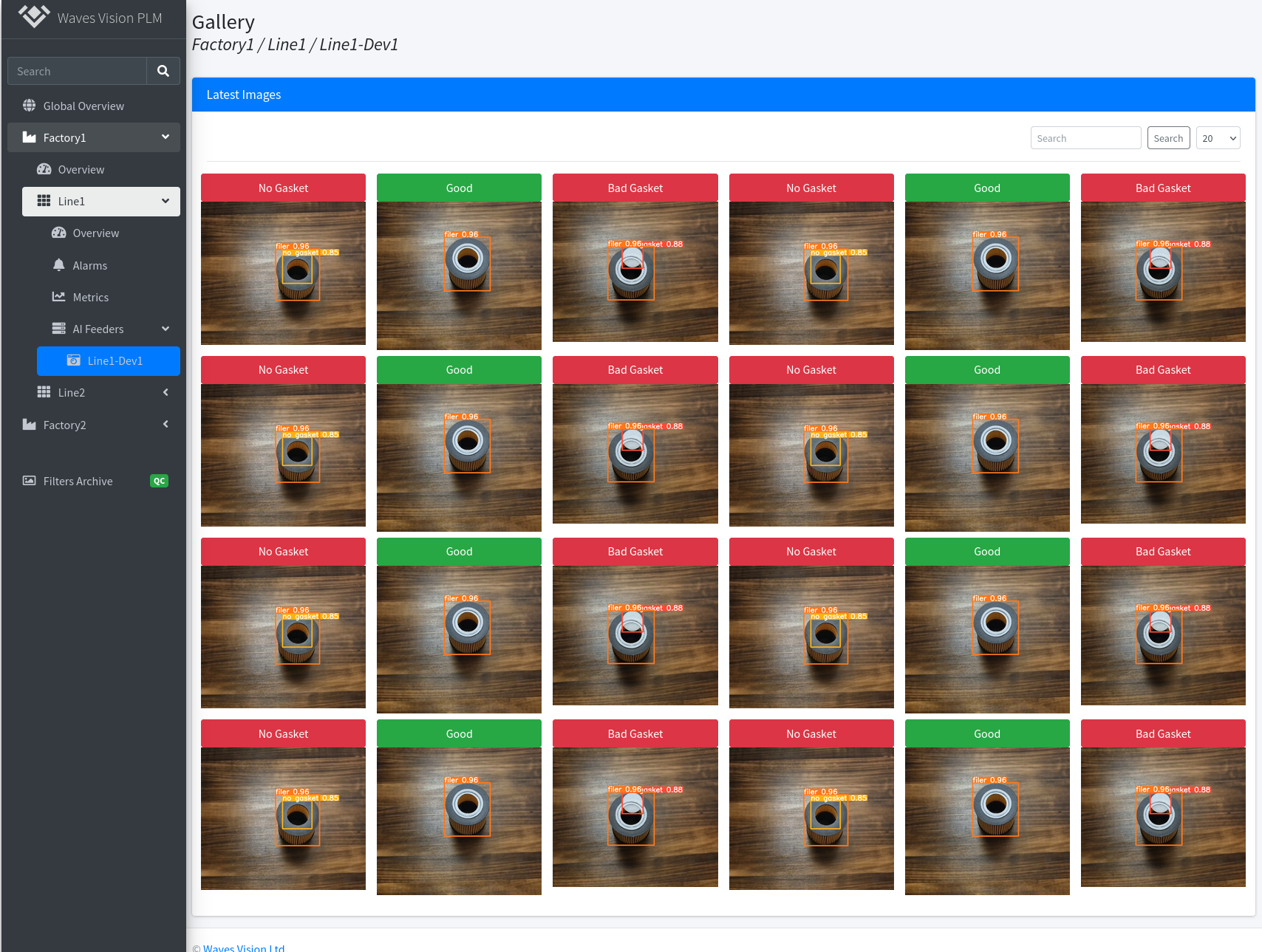

Maximize your manufacturing performance with our user-friendly dashboard, offering in-depth visibility into your operations. This interactive tool provides a detailed historical overview of production performance, including the number of items produced and all alerts generated across each production line. Additionally, we can retain historical images for five years or more, allowing for thorough review of any reclamation processes. With real-time reporting, you can monitor failures and productivity as they happen, empowering you to make informed, data-driven decisions. This not only drives continuous improvement but also ensures the consistent delivery of high-quality products that meet—and exceed—customer expectations.

- 24/7 Real-Time Monitoring : Continuously track your production lines with AI-powered image analysis, detecting defects and anomalies instantly.

- Proactive Alerts and Notifications : Receive immediate alerts for any detected issues, enabling swift action to prevent defective products from reaching customers.

- Analytics and Insights : Gain detailed visibility into your production performance with historical and real-time data, empowering you to make informed decisions and drive continuous improvement.

Support

Premium Support

Reduced Downtime

Our advanced 24/7 monitoring systems continuously provide health and performance insights for both hardware and software. This enables us to offer prompt remote support and timely interventions.

Remote Conectivity

Whether you prefer us to provide our own secure VPN services or utilize your existing, we ensure a reliable and encrypted connection to safeguard your data and maintain privacy.

Customer Satisfaction

Our customer needs are our top priority. We are committed to ensuring your complete satisfaction of our services.

Daily Backups

With daily backups, all your device data and settings are stored in a safe place. They can be restored whenever needed.

Hardware at your Location

Experience seamless service with us! We maintain a stock of spare components right at your location, eliminating the need for waiting during parts replacement.

Remote Restore

If there is a failure, we will promptly restore the last settings on your replaced devices.

Advanced

Camera Sensors

Next-Generation Camera Sensors.

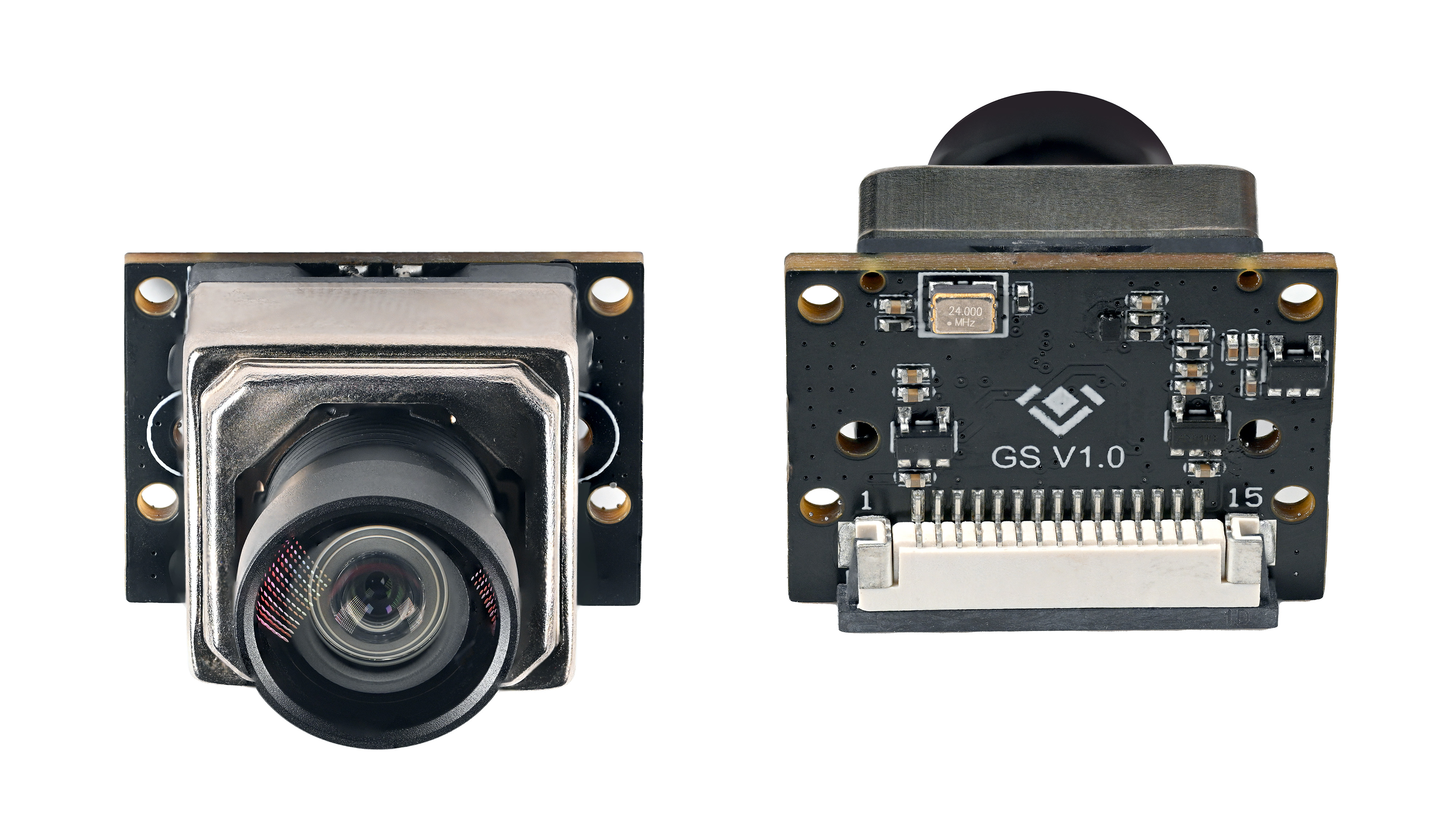

During our journey, we have developed a range of cutting-edge camera sensors tailored to meet diverse imaging needs. Our Global Shutter cameras are designed to excel in capturing high-speed moving objects with precision and clarity, making them ideal for applications that demand fast-motion imaging. Additionally, we have developed 4K near-infrared cameras that deliver exceptional performance in low-light environments, ensuring crisp and detailed video capture even in challenging lighting conditions. Furthermore, our 8K high-resolution cameras are built to provide unparalleled image quality, perfect for applications that require details and visual accuracy. All of these innovative solutions are now available to the wider public, offering advanced imaging capabilities to a broad range of industries and users.

You can explore our complete model list here!

Contact

Contact Us

Address

Bulgaria, Ruse, Borisova 27 Str.

Call Us